You might like

-

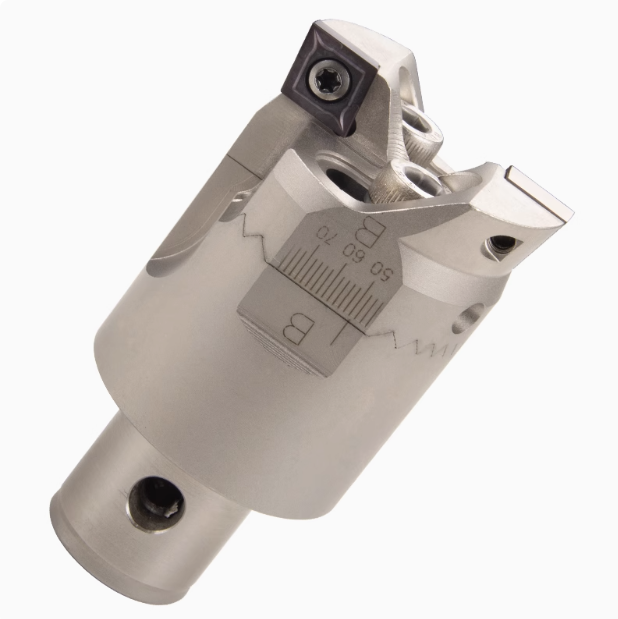

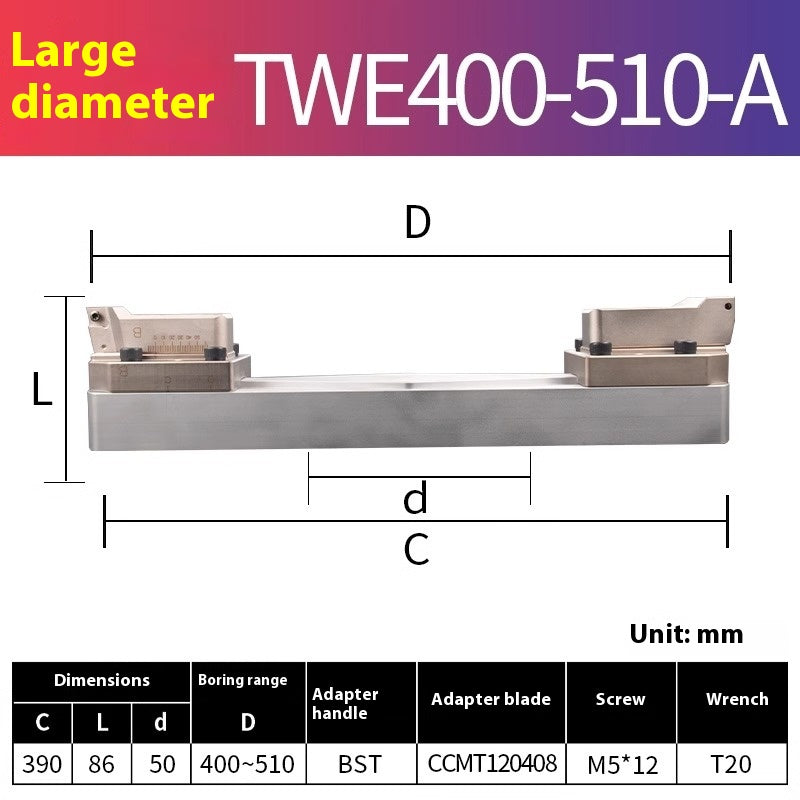

2048-Double-edged TWN rough boring cutter holder BT40 adjustable CNC deep hole boring head TWE CNC CKB/BST boring shankFrom $28.00From $28.00Sale Sold out

-

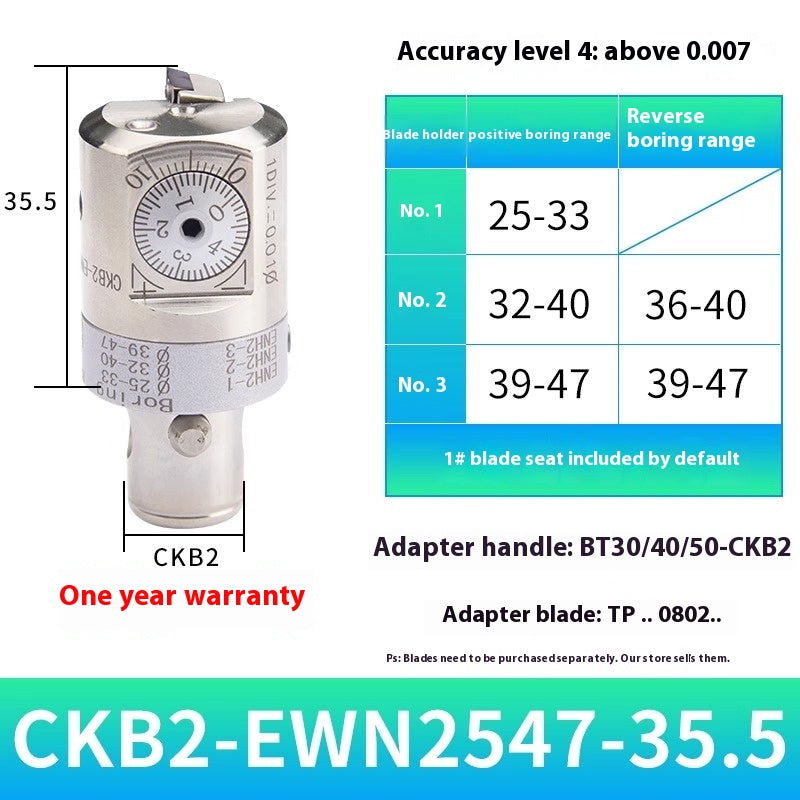

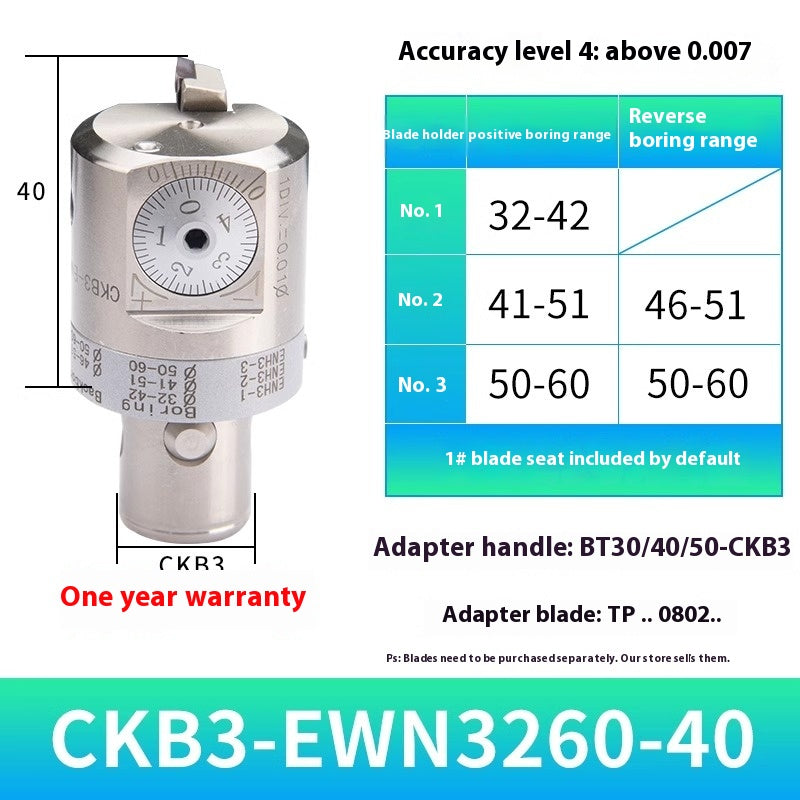

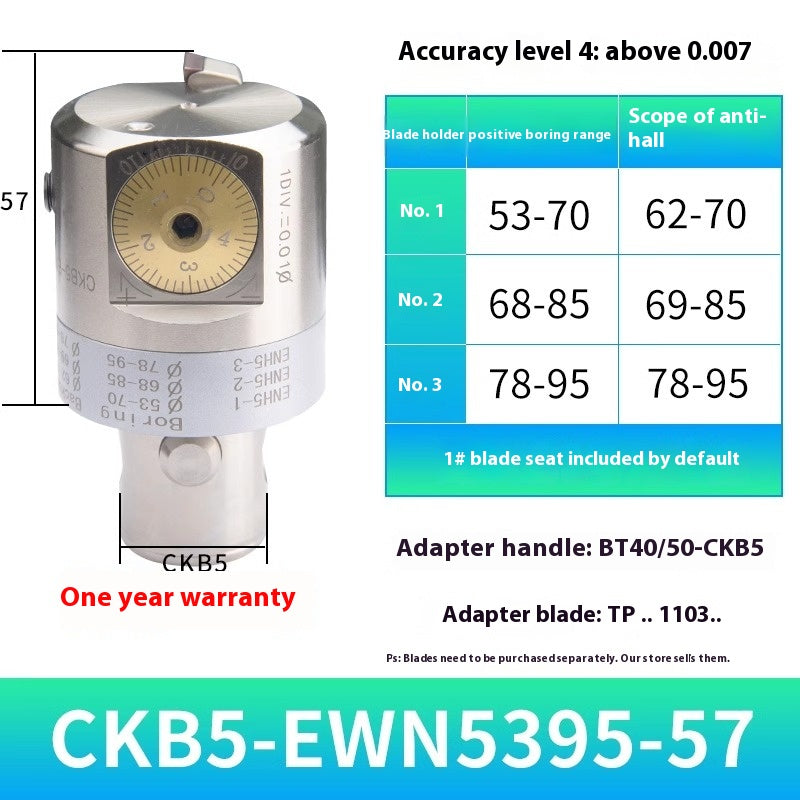

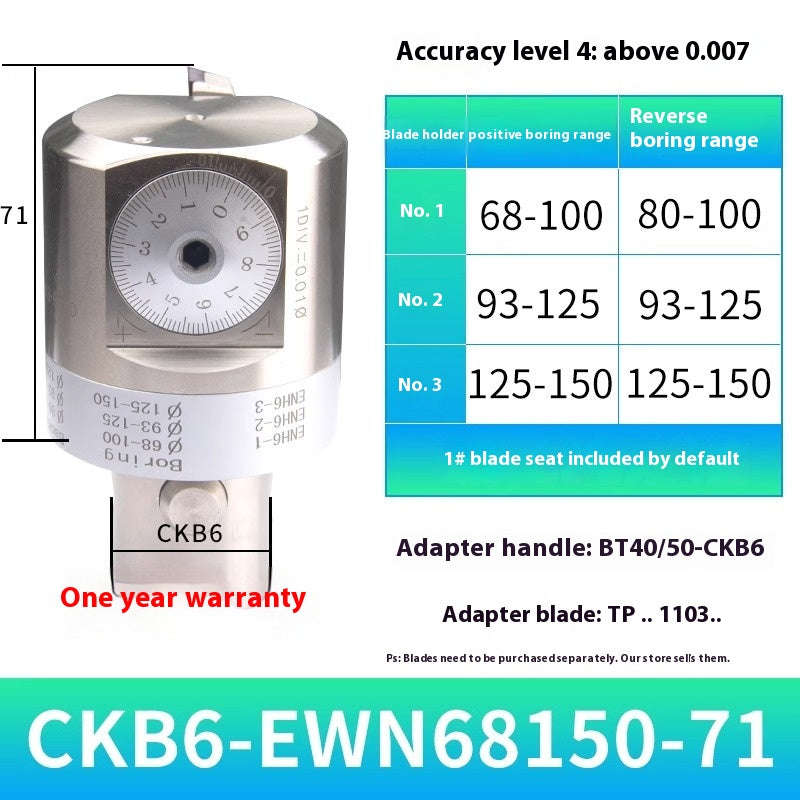

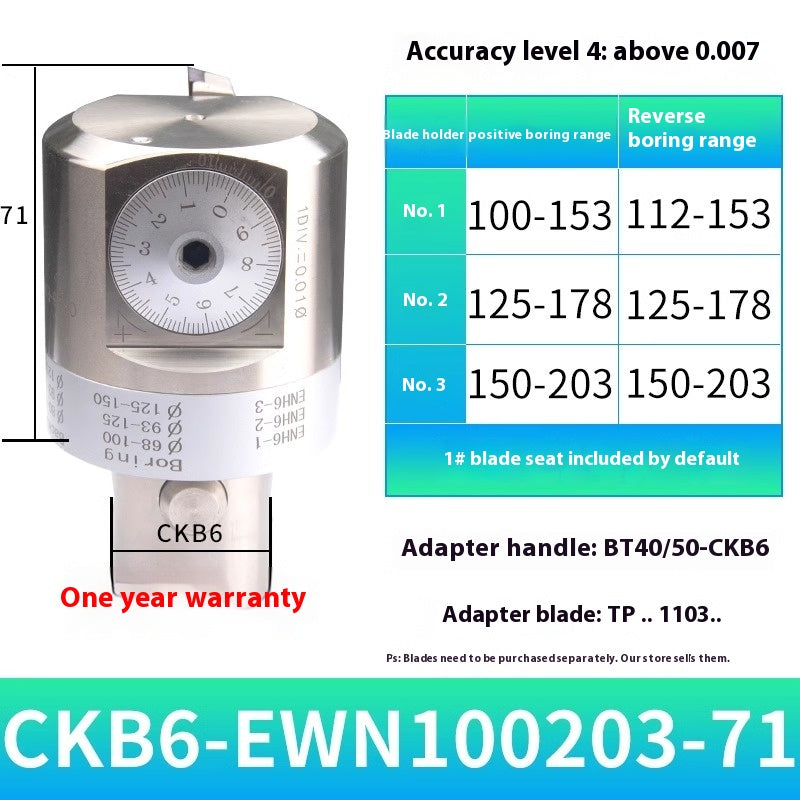

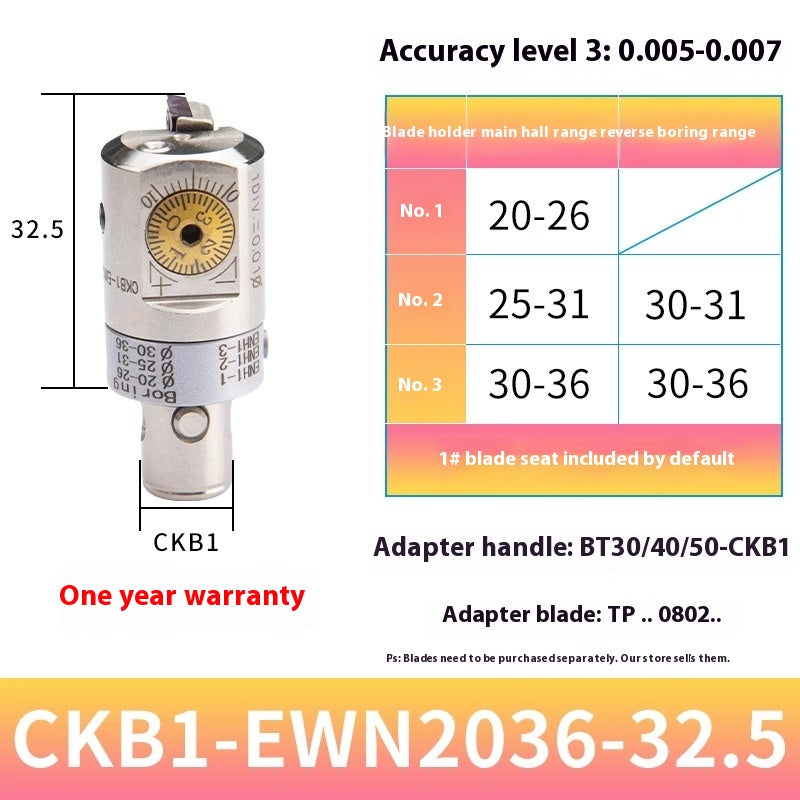

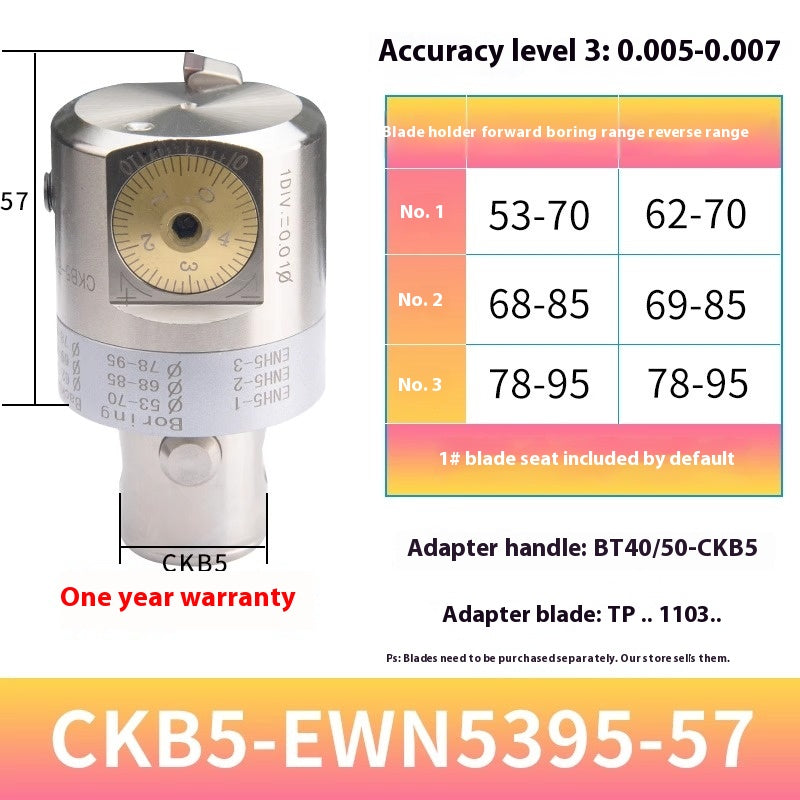

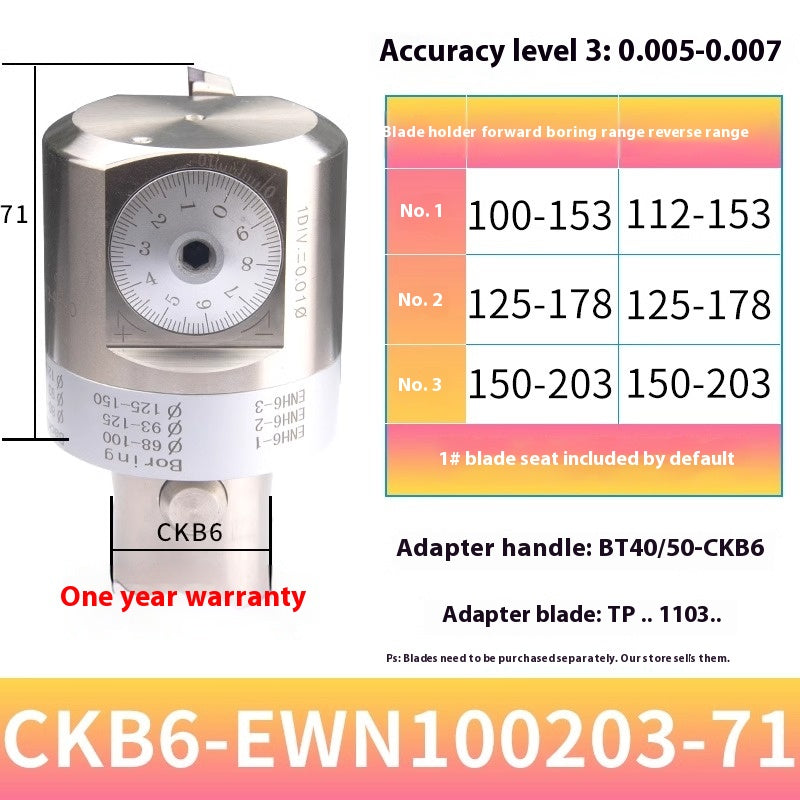

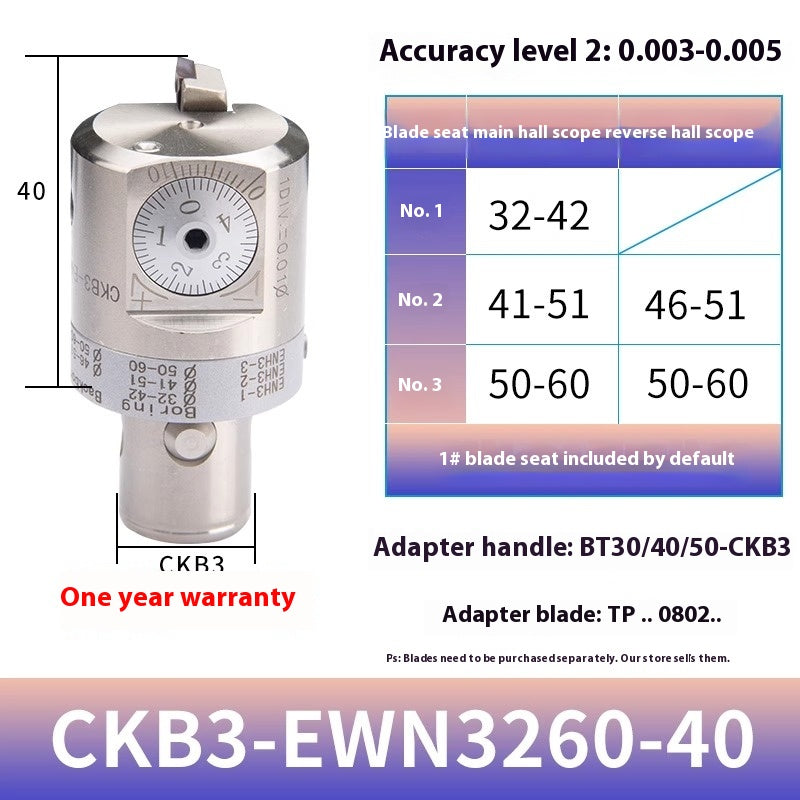

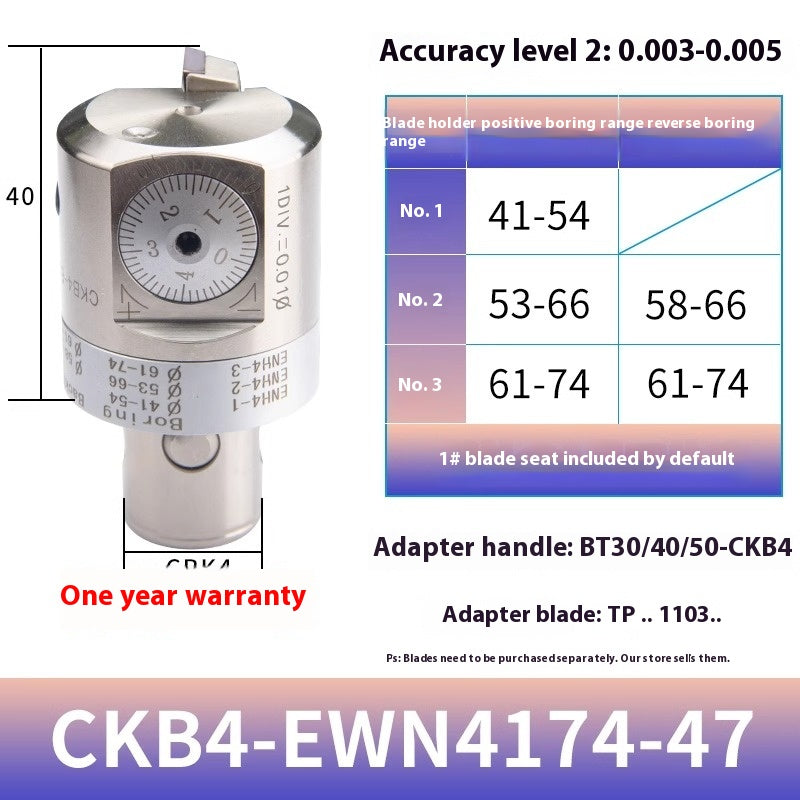

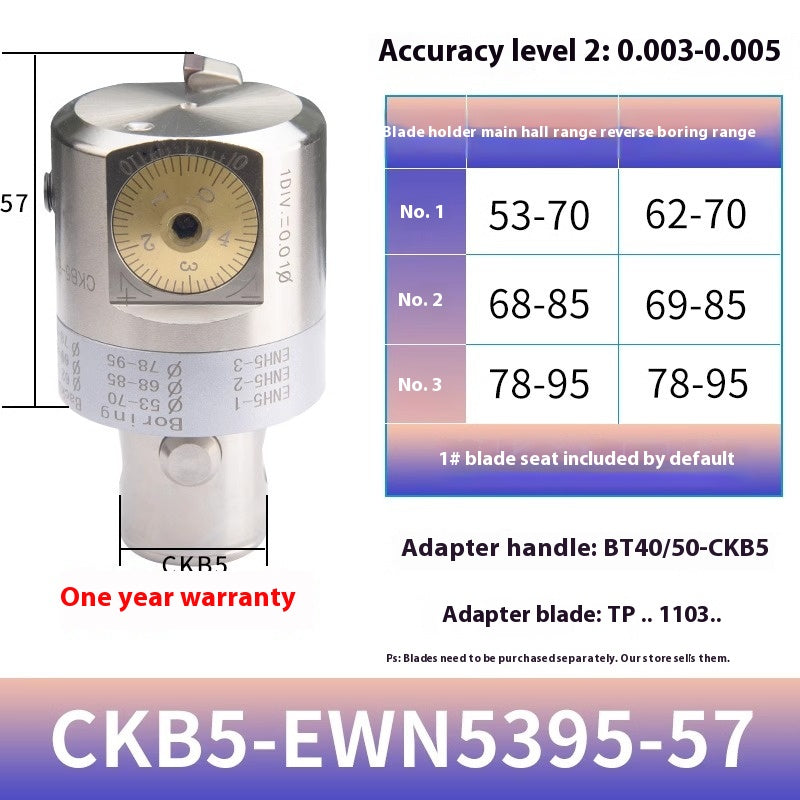

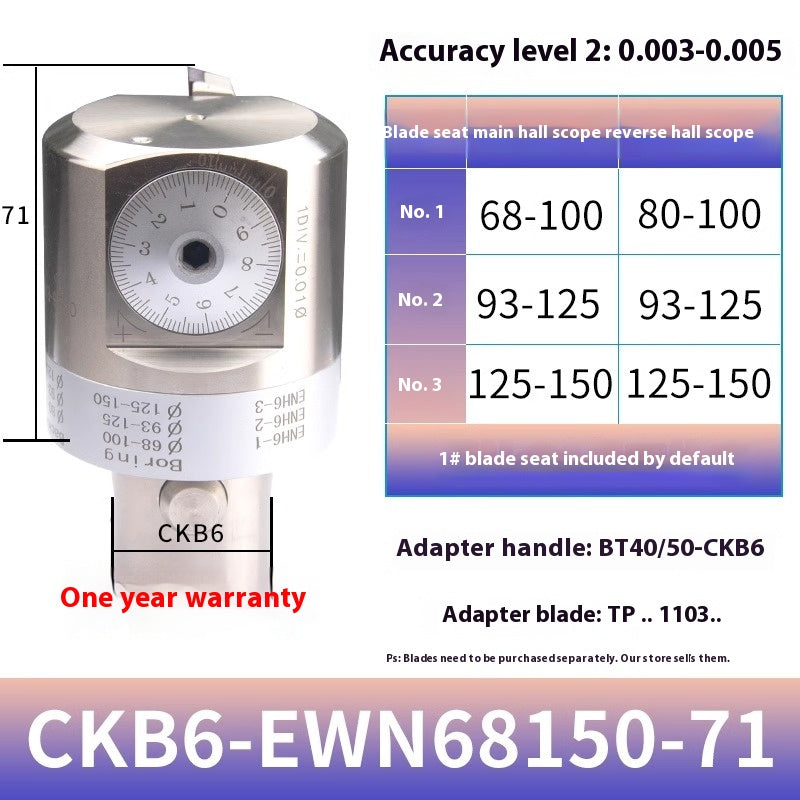

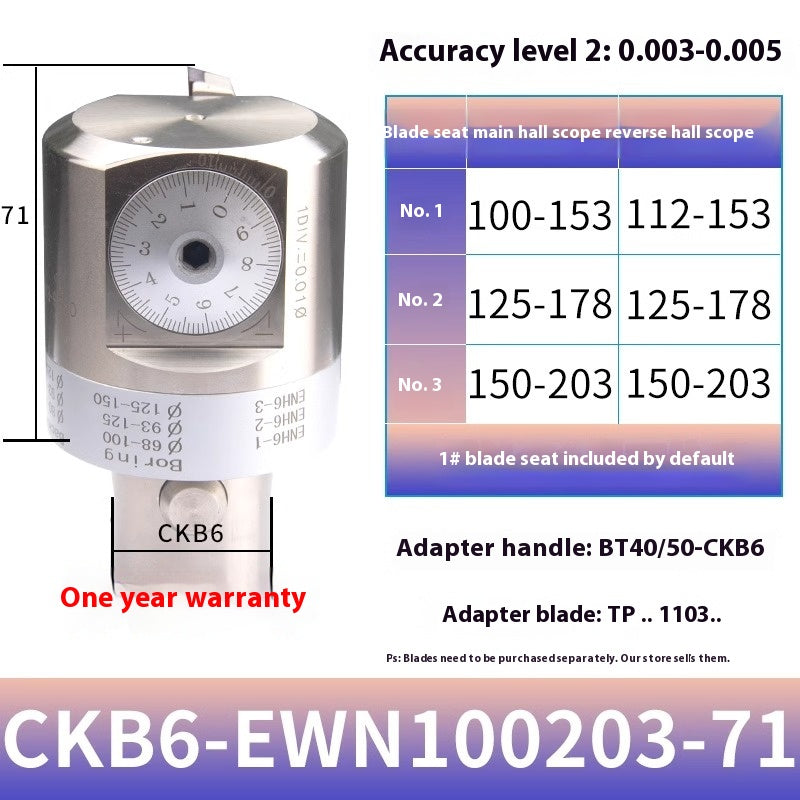

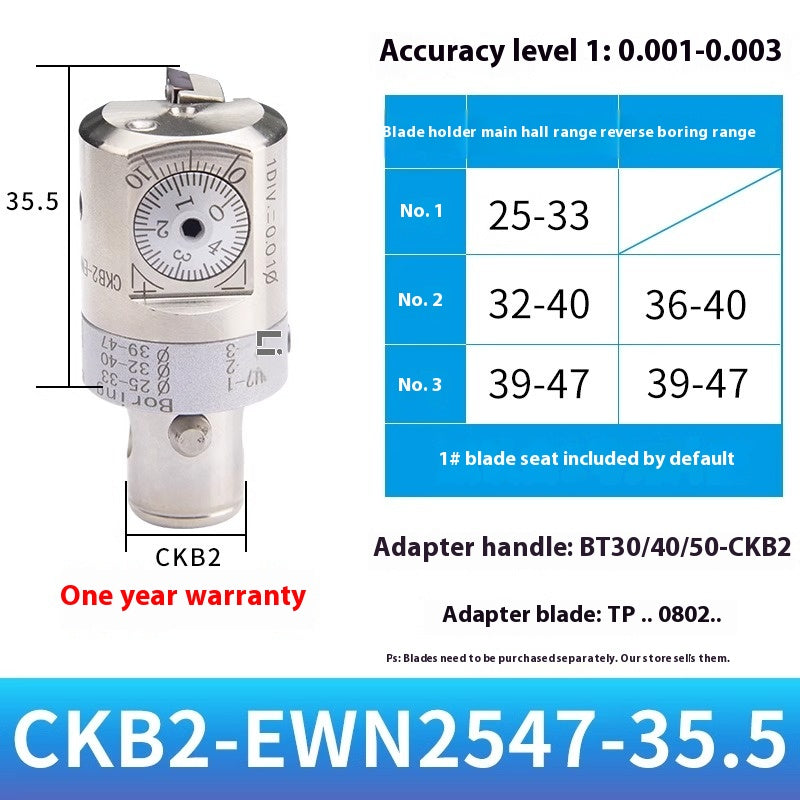

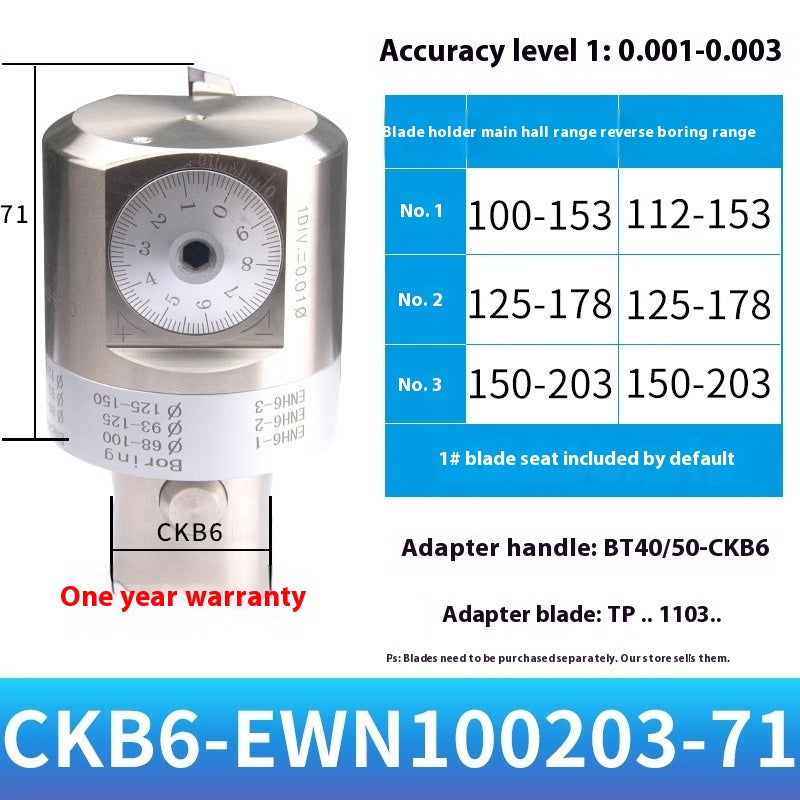

2049-Fine adjustment fine boring cutter adjustable boring head ENH insert holder machining center deep hole boring tool holder CKB boring shankFrom $55.71From $55.71Sale Sold out

Shopping cart (0)

Add WhatsApp + 8618254930096. Consult customer service to get freight cost reduced up to 99%.

00

Days

00

Hours

00

Mins

00

Sec

You might like

- Choosing a selection results in a full page refresh.

- Opens in a new window.